Han-Modular® Domino Modules

The next level of modular industrial connectors

Open up new possibilities for optimisation, including space and weight savings of up to 50%, thus reducing the CO2 footprint.

HARTING has accompanied and supported the industrial transformation for more than 70 years. In the 1940s and 1950s, the first successful products, electrical consumer goods for everyday use, laid an important foundation stone for the new beginning. The foundation for today's industrial transformation is formed by basic technologies such as interfaces for the transmission of power, data and signals. HARTING is therefore launching the Han-Modular® Domino modules, which will take the world of modular industrial connectors to the next level. They open up new possibilities for optimisation, including space and weight savings of up to 50%, thus reducing the CO2 footprint.

Supporting today's industrial transformation

Today, the world is once again facing the challenges of a major transformation. It is necessary to prepare for the future in order to meet challenges in the areas of energy and digitalisation, as this transformation requires enabling technologies.

Connectors represent such a technology by enabling the safe and error-free transmission of power, data and signals. Connector technology must also follow global megatrends and offer customers additional added value, such as sustainability.

Thus, HARTING presents the Han-Modular® Domino modules as the next development stage of the modular connector. The new series primarily meets the industry's requirements for saving installation space and weight. Users of Han-Modular® Domino modules can save up to 50% installation space by integrating different transmission types in one module, for example.

Lower energy costs and easy installation

The Domino module contributes to cost reduction and resource conservation. This is true for production because less energy and material are needed to manufacture smaller components. But it also applies to logistics, which benefit from the space and weight savings and also from more flexibility. Modularity is increased by the use of smaller components that can be arranged next to each other in hinged frames. Individual modules can be reused (in the sense of the platform idea); sustainability is improved.

Installers also benefit from shorter assembly times. Due to the reduced connector size, assembly areas that are difficult to reach can be equipped more efficiently or even opened up for assembly in the first place, e.g. in the narrow installation space of rail vehicles. As a result, assembly costs are reduced.

"Cubes" support customisation

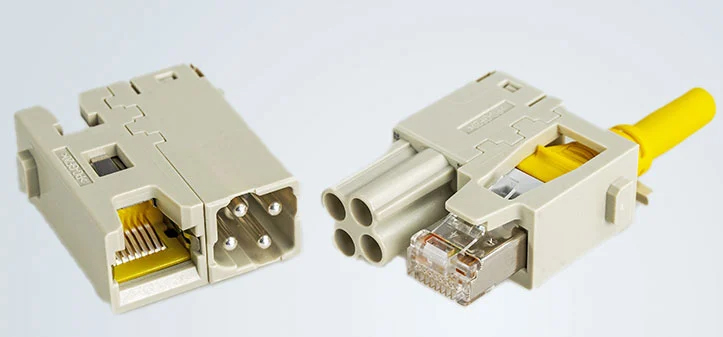

Just as dominoes have two separate squares, a domino module is made up of two building blocks or “cubes”. The Han-Modular® mating face is divided in two. The result is an almost square surface in which even larger contacts can be accommodated. The Cubes support the configuration of customized connectors that are precisely tailored to the requirements of a design. Power, signal, data or compressed air as well as male and female contacts can be combined in one module. Overall, the number of required interfaces per unit is reduced. The connection technology becomes smaller and more lightweight, more modules and module types than before fit into one connector.

Your benefits at a glance:

- Smaller and lighter connectors allow space savings of up to 50%

- Maximum flexibility as scalable to the respective need

- Reduction of installation times by combining several individual connections

- Compatible with the components of the Han-Modular® series, the market standard for modular industrial connectors

- Sustainability through consistent modularisation