Climate-friendly connectors are up to 50 % more energy efficient

Industrial companies are searching hard for ideas to massively reduce the power consumed by their production and thus also reduce their high costs. Their goal is to operate production facilities as energy-efficiently and climate-friendly as possible. Yet, it is also about maintaining their own competitiveness. This is because their high energy costs in manufacturing must be passed on to the consumers. The companies that take advantage of extensive potential for savings are able to retain customers.

By using connectors with low-impedance contacts, HARTING delivers a very energy-efficient power supply for industrial components. The potential for reduced electricity usage is significant.

50 % less energy usage in data centres – just with connectivity

HARTING came to a surprising conclusion in the recent study "Energy efficiency in data centres". HARTING's connectors with low-impedance contacts were compared with conventional standard CEE interfaces. The climate-friendly Han-Eco® connector provided a savings potential of up to 50 %.

You can discover the impact that using the proper connectors can have on your operating costs in the detailed calculations of the HARTING white paper "Achieving up to 50 % more energy efficiency by choosing the proper connector".

An opportunity for sustainability in industry

The results from this study have captured the attention of industrial companies with electricity-intensive manufacturing. The chance to improve energy efficiency while saving costs simply by implementing a different connectivity infrastructure is good news for many industries.

How data centres save up to €100,000 per year in electricity costs

The HARTING white paper on data centre energy efficiency also outlines various scenarios for hyperscale data centres. Depending on the price of electricity – which varies regionally and worldwide – different cost savings can be expected. An operator purchasing electricity in Europe can save electricity costs of around €100,000 per year using Han-Eco® connectors instead of CEE interfaces.The "data centre" example, however, also serves as an interesting blueprint for the industry.

Of course, the cost savings and increased energy efficiency through the use of climate-friendly components apply not only to data centres – they are achieved everywhere that Han-Eco® connectors are used. For example, in electricity-intensive manufacturing processes.

Han-Eco®: The climate-friendly connector that saves electricity and protects the environment

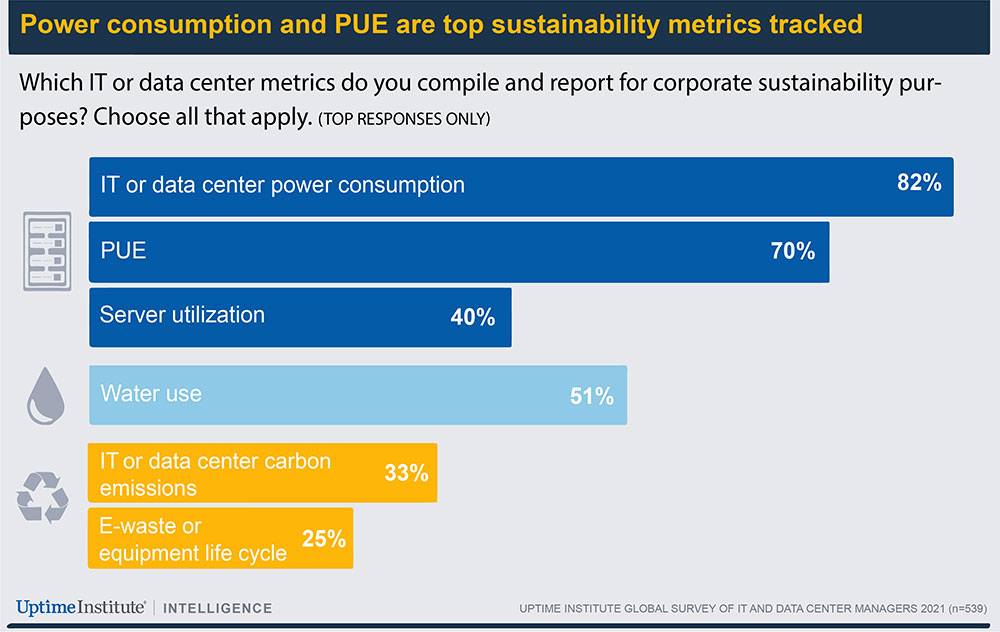

Power consumption and PUE as sustainability indicators

In a survey, approximately 80 % of data centre operators [1] reported that they closely monitor their data centre's power consumption and energy efficiency. Here, 70 % of the respondents relied on the PUE value as the key indicator. PUE (Power Usage Efficiency) is an important indicator for energy management.

Avoiding power outages

Data centre operators are well advised to regularly inspect the components they use in order to avoid power outages. HARTING connectors are perfect for the demanding requirements of data centres, because they transmit data, power and signals reliably and sustainably. A high-quality Plug & Play infrastructure reduces transmission losses, electricity costs and, thus, operating costs.

[1]Source: Uptime Institute survey, 2021

HARTING Han-Eco®. The climate-friendly connector compared to conventional CEE solutions:

- Minimises transmission losses

- Minimised voltage drop

- Transmits more power in the same space

- Less installation space required

- Cost-effective operations

- Quickly mounted in PDU (Power Distribution Unit) applications

- Components quickly replaced during service or maintenance

- Lightweight plastic housing

- Long service life

Actively supports reducing energy consumption in data centres