Simply paying without cash

Trade is almost as old as humanity itself. Exchange items and monetary payment types have been, and still are, changing continually. As digitisation continues its advance, payment types are changing again. While coins and bills are used less and less, accounts are being settled increasingly in bits and bytes. The systems required for payments are becoming smaller and more compact as the miniaturisation trend continues. HARTING's har-flex and har-flexicon series are the best solutions for printed circuit boards in detection devices when you need robust, space-saving PCB connectors.

Cashless payments are becoming more popular and easier to use. Refuelling, shopping or simply buying a new T-shirt: all paid for with a plastic card of course. Hi-tech key fobs or NFC-enabled (Near Field Communication) smartphones can also be used.

One company that makes the necessary reading equipment is the Swiss company MICROTRONIC AG. They are continually developing new and smaller readers and expanding payment systems with new features. The current contactless payment system supports a variety of RFID technologies: including Mifare Classic, Plus, DESFire, CALYPSO and, in the future, HID iClass. Another highlight is the EMVCo-certified vending reader, which enables cashless payment using VISA or MasterCard.

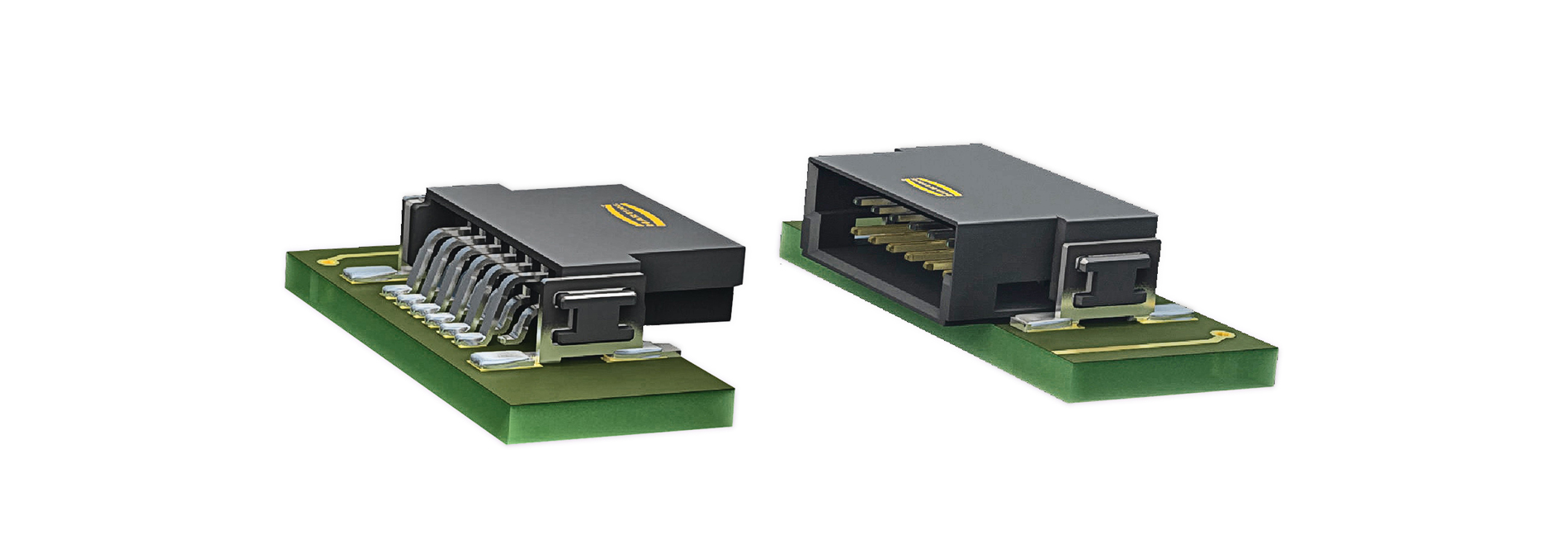

The miniaturisation of these readers constantly presents the manufacturer with new challenges. The devices should become smaller with more usability but should not lose their robustness and reliability. The new generation of MICROTRONIC readers, for example, requires not only compact single-conductor wiring but also the corresponding device-internal board-to-board interfaces. While MICROTRONIC AG used connectors with 2mm pitch in the past, the company now relies entirely on HARTING's har-flex® series PCB connectors. With a pitch of 1.27 mm and continuous availability of poles from 6 to 100, the har-flex® supports extremely compact device designs while maintaining permanent robustness.

If individual conductors need compact connections to the board, har-flexicon is the HARTING solution that can be wired up in the field. A key requirement of modern device is versatile, single-conductor wiring for industrial devices that have printed circuit boards as their main components.

With a contact pitch of only 1.27 mm, reflow and SMD soldered components deliver cost benefits in the manufacturing process because of their uniform and automated assembly/soldering processes.